|

wedge wire pipes application &method of cleaning

Inquiry now

|

Frequently Asked Questions |

|

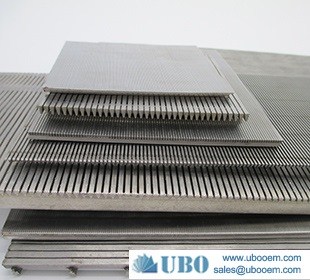

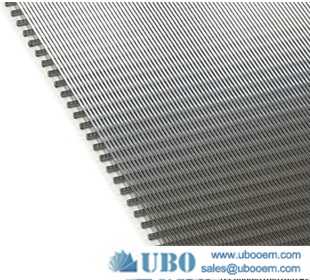

V shaped wire welded stainless steel 304 screen flat panel are widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection and other industries. For sieving liquid, powder and other materials. In petroleum, chemical industry, metallurgy, mining, pharmaceutical purification and drilling liquid purification.

Inquiry now

|

Wedge Wire Screen |

|

V shaped wire welded stainless steel 304 screen flat panel has sturdy constriction and good mechanical property

Inquiry now

|

Wedge Wire Screen |

|

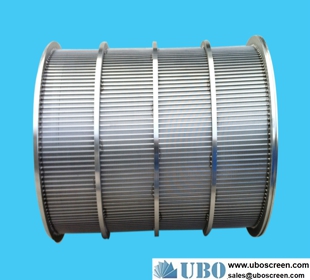

drum screeUsage: Liquid Filter Type: Perforated Metal Mesh Material: Metal Hole Shape: Square Filter Rating: more than 90% Thickness: as per your request Length: as per your request Width: as per your request Technique: welded Mesh Size: 0.5-2mm Wire Gauge: 2-3mm color: white Application: Screen ,n baskets,

Inquiry now

|

Wedge Wire Screen |

|

With 10 years’ export experience, our Flat welded Wedge Wire Panel has been welcomed in international markets. Welcome to contact us.

Inquiry now

|

Wedge Wire Screen |

|

V wire welded wedge wire mesh filter can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen”s construction.

Inquiry now

|

Wedge Wire Screen |

|

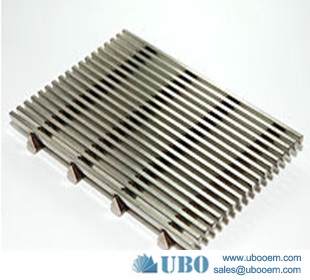

WEDGE-FLOW is our own brand of industrial grade wedge-wire. It is specially constructed to resist clogging, while maximizing open area and ensuring required particle retention through precise slot sizes. Our screens are designed to provide uniform low velocity throughout the entire screen surface, which all but eliminates screen blockage and plugging. By specifying a low through-slot velocity, leaves, algae, and aquatic life continue on their way without being drawn into your process stream or covering-up the outer surface of the intake screen.

Inquiry now

|

Wedge Wire Screen |

|

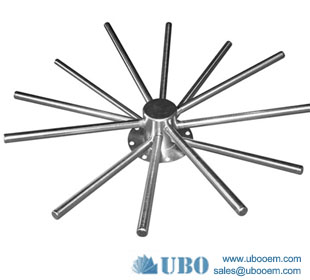

Header-Lateral System For the treatment of process water such as in ‘Ion Exchange’ and in the process of removing organic matter, Completion Products offers products such as the Header-Laterals Systems to uniformly collect and distribute process flow. Sizing of both the main header pipe and the screen laterals are based on recommended through-pipe and slot opening velocities to ensure higher efficiency and lower pressure drop. Sizing of the slot size is also critical to ensure that there is no resin/media leakage. The screen laterals (screen-based or screen + drilled pipe-base) are removable and can be designed with either a flange or threaded nipple connection.,

Inquiry now

|

Wedge Wire Screen |

|

Ubo Filter Co.,Ltd is specialized in producing and distributing Mine sieving mesh,Water well screen,Well screen,Oil well screen,Wedge wire screen,Slot tube,V shaped wire welded screens,Spiral screen tube,Wire-wrap screen pipe,Mine screen mesh,Screen cylinders,Vibrating sieve screen plate. , Welcome to contact us for more information and cooperation.0086-0311-83289301

Inquiry now

|

Wedge Wire Screen |

|

Activated Carbon Bed Regeneration Water well screen,Mine sieving mesh Effective and economic effluent treatment is the key element to successful, compliant waste management. Gap Technology Ltd have developed our wealth of design and manufacturing experience to offer bespoke Wedge Wire solutions for water treatment and clarification, achieving high levels of suspended solids reduction for industrial and municipal applications.,

Inquiry now

|

Wedge Wire Screen |

|

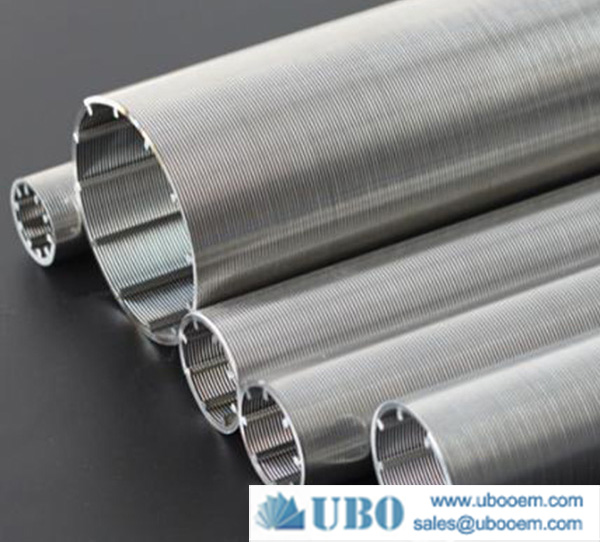

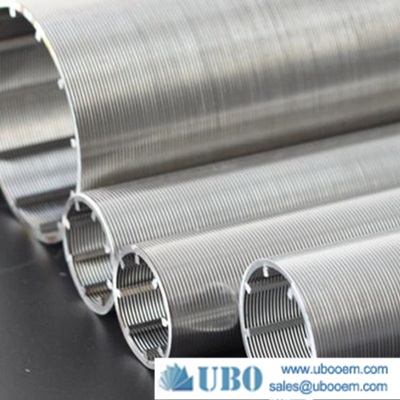

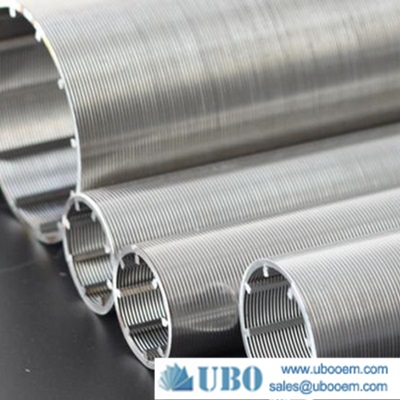

V-wire Screen is manufactured with V-shaped profile wire, which is spirally wound around a cage of longitudinal support rods.,Each intersecting point of these wires if fusion welded. The pitch of winding gives different spacing between two adjacent turns of wire.

Inquiry now

|

Wedge Wire Screen |

|

Stainiess steel strainer nozzle is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

The wedge wire screen nozzles. Nozzles are closed on one side and have a threaded fitting on the other. The screen nozzle with thread coupling can be fixed on the filtering equipment for the filteration of water petrol resin and other medium.One rubber shim , one steel shim and two thin nuts of the same material for a nozzle.

Inquiry now

|

Wedge Wire Screen |

|

Wire wrapped stainless steel wedge wire screen meshs are made up of rods and wire. The rod can be round wire, triangular wire or trapezoid wire. The wire is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, water well screens have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Inquiry now

|

Wedge Wire Screen |